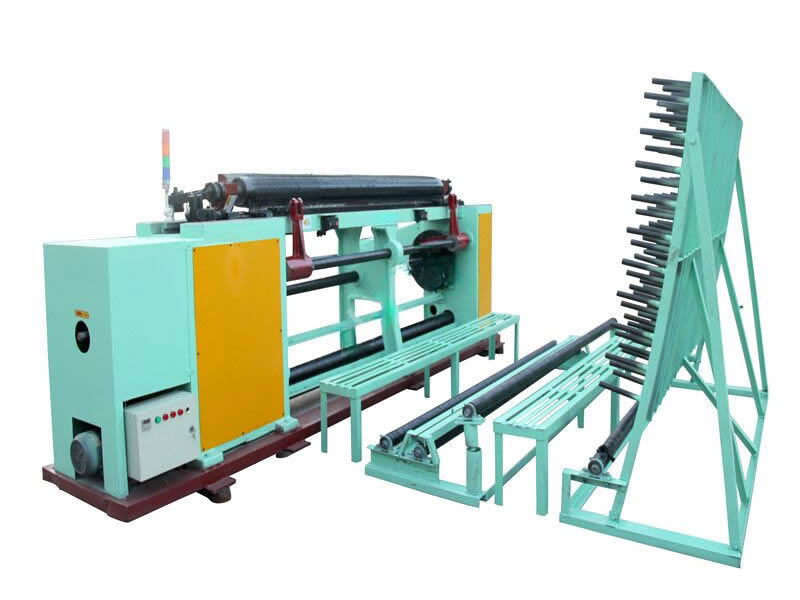

Hexagonal Wire Mesh Machine, also known as Chicken Cage Netting Machine or Double Twisted Hexagonal Mesh Machine, is specifically designed for producing hexagonal wire mesh. This type of mesh is widely used for a variety of applications such as fencing for farmland, poultry enclosures, reinforcement of building walls, and other separation nets.

Features:

- High-Speed Production: The machine allows continuous, efficient production of hexagonal wire mesh.

- Stable Operation: It operates smoothly with minimal noise and includes features such as automatic stopping for broken wires, broken nets, and a preset length warning system.

- Precision Mesh: The resulting mesh is uniform, tightly woven, and can include optional ribs for reinforcement.

- Flexible Design: It offers the ability to customize mesh sizes by using optional additional parts and equipment.

- Durable and Easy to Operate: The machine is built for longevity and requires simple maintenance, with centralized lubrication to ensure smooth operation.

Operation:

The machine operates by using pinions on the front and rear racks to weave wires fed from bobbins and spiral coils into a hexagonal mesh. Wires are placed into the holes of the pinions, and as the machine runs, it continuously produces the mesh until it reaches the desired length—standardly 45 meters—after which it can be cut. The machine’s capability for continuous operation, along with its smooth and low-noise performance, makes it highly efficient for large-scale production.

Applications:

- Agricultural Fencing: Ideal for creating fences to enclose grazing areas for animals such as chickens, rabbits, ducks, and geese.

- Building Reinforcement: Used for reinforcing walls and insulation in construction projects.

- Protection and Separation: Suitable for creating protective barriers and separation fences for various uses.

Components:

- Bobbin Winding Machine and Spiral Winding Machine: These auxiliary machines are essential for preparing the wires, feeding both from bobbins and spiral coils into the main machine to produce the mesh.

- Optional Equipment for Mesh Sizes: Additional main racks and parts are available as optional equipment to produce different mesh sizes, including openings of 1″, 1¼”, 1½”, 2″, and 3″.

TECHNICAL PARAMETERS

| MODEL | MESH WIDTH(MM) | NETTING WIDTH(Meter) | WIRE DIA(MM) | SPEED (Meter) | OUTSIDE DIMENSIONS(Meter) | MOTOR(KW) | WEIGHT(Ton) |

| 1/2″ | 15×22 | 1.5-4.7 | 0.35-0.7 | 60 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 3/4″ | 20×35 | 1.5-4.7 | 0.35-0.7 | 80 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 1″ | 25×38 | 1.5-4.7 | 0.35-1.2 | 90 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 1.2″ | 30×40 | 1.5-4.7 | 0.35-1.2 | 100 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 1.5″ | 40×53 | 1.5-4.7 | 0.5-2.0 | 140 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 2″ | 50×85 | 1.5-4.7 | 0.6-2.2 | 160 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 3″ | 80×100 | 1.5-4.7 | 0.6-2.4 | 180 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |

| 4“ | 100×140 | 1.5-4.7 | 0.8-3.0 | 200 | 4.2-6.2X1.7X1.6 | 3.0 | 4.2-5.5 |