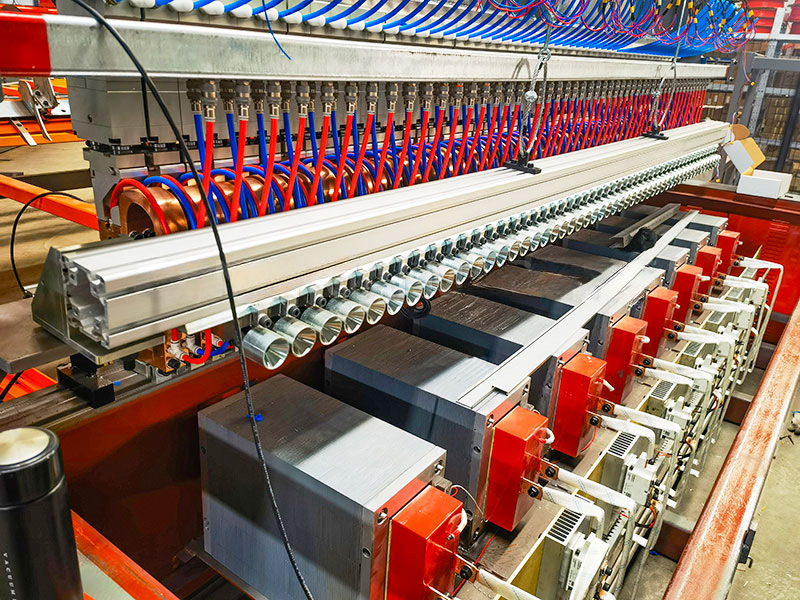

Fence Panel Welding Machine also known as the 3D Fence Panel Mesh Welding Machine, are engineered to produce a wide range of high-quality fence panels tailored to your specific needs. Equipped with a PLC (Programmable Logic Controller) control system and intuitive touch screen input, these machines offer intelligent, efficient, and user-friendly operation.

Features:

Intelligent Control System:

- PLC with Touch Screen and Keyboard Input: Offers dual input methods for greater flexibility and ease of use, making the machine more intelligent and user-friendly.

- Electrical Synchronous Control Technology: Ensures precise welding and central control through a sophisticated PLC program system.

Versatile Wire Feeding Options:

- Line and Cross Wire Feeding: Both wires can be fed from pre-cut wires or off-coils, depending on production requirements.

- Automatic Cross Wire Feeding: Features multi-hopper systems that automatically feed cross wires, enhancing production efficiency.

- Optional Automatic Line Wire Feeding: While line wires can be manually placed, an automatic feeding option is available to further increase efficiency.

High Production Efficiency:

- European Welding Technology: Utilizes advanced welding techniques to significantly boost production rates.

- Servo Motor Mesh Pulling: Employs servo motors for repeated and precise mesh pulling, ensuring consistent quality.

Adjustable Mesh Specifications:

- Variable Wire Thickness: Handles wire diameters ranging from 2mm to 8mm, accommodating various fence panel types including 6-5-6 and 8-6-8 configurations.

- Customizable Width and Spacing: Mesh widths from 1500mm up to 3700mm, with line wire spacing starting from 25mm.

- Infinitely Adjustable Cross Wire Steps: Allows for random adjustment of weft distances on the same mesh sheet.

High Welding Quality:

- Individual Cylinder Control: Each welding head is controlled by its own cylinder, ensuring uniform welding pressure and strong, flat welds.

- Stainless Steel Compatibility: Capable of working with almost all types of stainless steel, broadening application possibilities.

Ease of Operation and Maintenance:

- Minimal Staffing Requirements: The entire production line can be efficiently operated by just two staff members.

- Durable Components: Incorporates foreign-brand electronic components for extended service life and reduced maintenance costs.

Customization and Auxiliary Options:

- Tailor-Made Solutions: Machines can be customized to meet specific client requirements, including auxiliary devices and accessories.

- V-Pressing Capabilities: Offers both in-line and separate V-pressing options to suit different production needs.

- Various Stacking Methods: Supports every type of stacking, providing flexibility in post-production handling.

Applications:

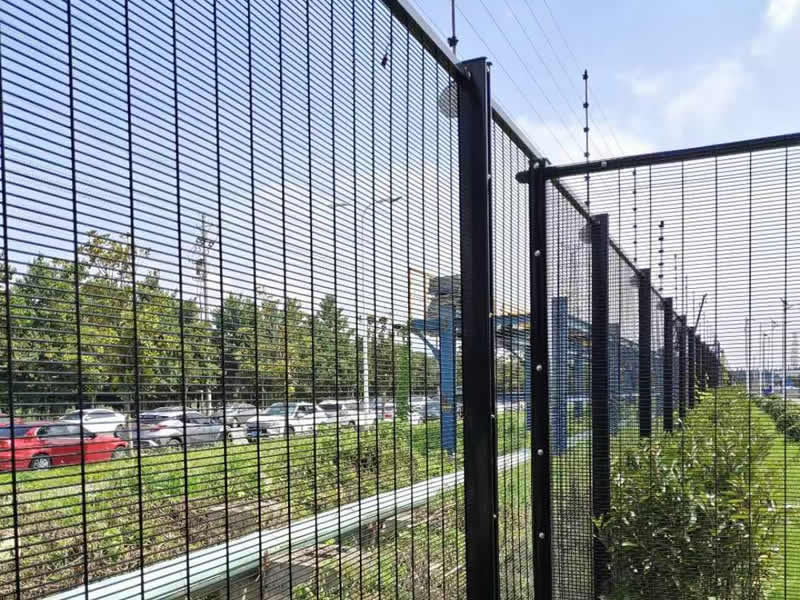

The 2D and 3D fence panels produced by our machines are constructed from high-quality steel. To enhance aesthetic appeal and resist corrosion, the panels are typically galvanized and then coated with paint. This process results in a neat appearance, suitability for harsh weather conditions, and long-lasting durability.

- Road and Railway Safety: Manufacturing fence meshes for highways, railways, and airport bridges to enhance safety and security.

- Industrial Facilities: Creating enclosures for factories and warehouses to ensure internal safety and asset protection.

- Residential Areas: Providing secure and private fencing solutions for housing developments and residential communities.

- Public Infrastructure: Producing fences for parks, airports, stations, stadiums, and other public facilities.

- Storage Solutions: Crafting mesh panels suitable for goods shelves and storage racks in commercial settings.

Main parameter of welded mesh fence machine IVI-01:

| Wire diameter | 2.8-3.2mm | Rated voltage | 380v |

| Welding aperture | 50*50-200*200mm | Rated electrical power | customized |

| Width of mesh | 1200mm | Overall dimension | 1.8*2.5*1.8m |

| Number of electrodes | customized | Machine weight | 3.2T |

| Welding speed | 60 times/min |

Main parameter of welded mesh fence machine IVI-02:

| Wire diameter | 3-6mm | Rated voltage | 220V/380 V |

| Welding aperture | 50×50-400x400mm | Rated electrical power | 50-60Hz |

| Width of mesh | 2500mm | Overall dimension | 4.3mx2.8mx1.4m |

| Number of electrodes | customized | Machine weight | 4T |

| Welding speed | 50 times/minutes |